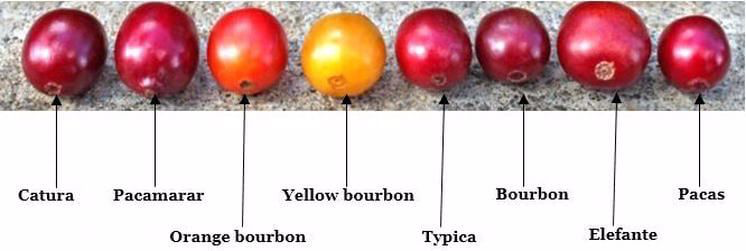

When it comes to the flavors of your favorite coffee, it all comes back to the coffee cherry. Yes, environmental factors such as the altitude the coffee was grown at, the growing region, and the soil all play a major role in the flavors you experience. You’ve got factors such as the varietal, shown below and talked about more in our Where Coffee Comes From blog.

Still, one of the easiest “hacks” to finding your new favorite coffee is to pay attention to the processing method on the Klatch bag in front of you.

The coffee cherry is made up of layers, and each processing method leaves on all, some, or none of the layers outside of the coffee bean or seed. Some processing methods, such as Anaerobic Slow Dry (ASD) or Anaerobic Natural, also let the cherry ferment in an oxygen-free environment, which brings out fruit-forward flavors in a rich, bold way.

An example of this would be our Panama Elida Natural Catuai, described by roastmaster Mike Perry as, “A fruit BOMB!” during cupping. For more about what a coffee cupping entails, check out our Vlog: Cupping and Conversation.

Natural Process

During the natural process, coffees are laid out to dry with the coffee cherry intact. No layers are removed. This process is also known as the dry process, and is the oldest method of processing. Because the coffee seeds have time to dry with the coffee cherry surrounding them, natural process coffees tend to be more fruit forward, as well as full-bodied.

After the coffee cherries have had time to dry, the skin (or pulp) and mucilage layers are removed, and the green coffee is stored and given time to “rest” before exporting.

Different processes are used for different coffee growing regions, depending on environmental factors. Natural process works best in dry climates, since it’s challenging to ensure that no mold gets into the bean with the coffee cherry attached. Since natural processed coffees are picked and laid out to dry without an additional washing process, natural process also works well in areas where water is scarce.

One of Klatch’s recent natural process coffees is the Colombia Tolima Dulce Natural, with cupping notes of plum, lemon, and caramel. Grown in soil with clay minerals and sealed and fermented for 46 hours, the fruit forward flavors of the Tolima are reflective both of the environment and the natural processing method.

Washed Process

During the washed process, the coffee cherry is depulped and “washed” with water. Washed process coffees tend to be dryer, brighter, and more acidic. The flavors “locked” in the bean from factors such as soil, varietal, and region shine through.

Washed process is also known as “wet processing” because the beans are washed with water. After the skin of the coffee is removed by a depulping machine, the beans are placed into fermentation tanks until the mucilage layer is no longer sticky. The mucilage is broken down during both the controlled fermentation process and during an additional washing process.

Two of Klatch’s new washed process coffees, our El Salvador Las Mercedes Pacamara Washed and Rwanda Kamina Washed, have won awards and are two of our favorites around the office.

Our Rwanda Kamina Washed has a sweet flavor profile, with notes of nectarine, honey, and herbal tea, and has won numerous awards in Rwanda’s Cup of Excellence competition.

Our El Salvador Las Mercedes Pacamara Washed is a cleaner and sweeter Pacamara, with flavor notes of blood orange, caramel, and meringue. Pacamara Wash was awarded “Best Coffee of Origin-Tecapa Chinameca” in 2019.

Honey Process

Honey processed coffees are in between natural and washed process in the number of layers of the coffee cherry that are removed. Coffees are depulped, removing the fruit and skin, but the “mucilage” layer is left intact. The mucilage layer of the coffee cherry is sweet and sticky, like honey. Honey process coffees have both the sweetness of naturals and the brightness of washed process.

There are variations within honey process, based on the percentage of mucilage that is left intact. Typically, there are 4 variations: white honey, where 80-100% of the mucilage is removed, yellow honey, where 50-75% of the mucilage is removed, red honey, where less than 50% of the mucilage is removed, and black honey, where as little mucilage is removed as possible.

Honey process was first popularized in Central America, Costa Rica specifically. Honey process techniques were first developed to save water and enhance flavor. For one of our farming partners, Las Lajas, run by Oscar and Francisca Chacón, innovation was birthed out of bold business moves and endless experiments.

In 2005, after years of delivering their coffee cherry to a cooperative for the going market price, they decided to join the “micromill revolution” and purchase their own depulper to ensure more control over the quality and price received for their lots. “At first, we didn’t know what we were doing,” Oscar explains. “We were just experimenting.” That experimentation led to some of the most exciting flavor profiles we have ever tasted. Now, the Chacóns produce a wide range of Honey Process coffees, tweaking the drying time to create different effects in the cup.

Our new Costa Rica Finca Garcilaso H15 Anaerobic Natural is almost like a honey process with sweet, dry, and complex flavor notes of lingonberry, kiwi, and loganberry.

Wet Hulled Processing Method

Giling Basah, or wet hulling, is the traditional method specific to Indonesia. This is the process used for our Organic Sumatra Ratu Ketiara Mandheling Gr1 Fair Trade, and the method used for Sumatra origin coffees overall.

Processing methods that would work well in a dry climate, such as laying the coffee cherries out to dry in the sun (natural process), don’t work well in the humid, island climate of Sumatra. The wet hulling method differs in timing depending on the producer, but generally consists of:

- Putting the beans through a depulper machine to remove the skin

- Fermenting overnight to break down the mucilage on the bean, then washing it off

- Once the mucilage is removed, what is called wet parchment coffee is left. This is able to be left out in the sun

- The beans are put through a huller that is specifically designed for the semi-dried parchment

- The beans are laid out in the sun during the day, and stored in bags overnight to continue fermenting

For more on the wet hulling process, check out this article from Perfect Daily Grind.

Processing Methods, Coffee Seasons

Each processing method and drying method takes a different amount of time, and harvest times are specific to each region and dependent on environmental factors. If you’ve found a processing method or region that you especially enjoy, it might be helpful to check out our Coffee Seasons blog. Different coffees are available at different times of the year.

If you’re still learning which flavor notes you enjoy in your coffee, take our Find Your Beans quiz!